Pattern

flow and activity relationship

In determining the requirements of a

facility, three important considerations are flow, space, and activity

relationships.

• Flow depends on lot sizes,

unit load sizes, material handling equipment and strategies, layout

arrangement, and building configuration.

• Space is a function of lot

sizes, storage system, production equipment type and size, layout arrangement,

building configuration, housekeeping and organization policies, material

handling equipment, and office, cafeteria, and restroom design.

• Activity relationships are

defined by material or personnel flow, environmental considerations, organizational

structure, continuous improvement methodology

Activity

Relationship

Activity

relationships provide the basis for many decisions in the facilities planning process.

The primary relationships are considered are

1.

Organizational relationships, influenced by a span of control and reporting relationships.

2.

Flow relationships, including the flow of materials, people equipment, information,

and money.

3.

Control relationships, including centralized versus decentralized materials control,

real time versus batch inventory control, shop floor control, and levels of

automation and integration.

4.

Environmental relationships, including safety considerations and temperature, noise,

fumes, humidity, and dust.

5.

Process relationships other than those considered above, such as floor loading,

requirements for water treatment, chemical processing, and special services.

Several

relationships can be expressed quantitatively; others must be expressed qualitatively.

Flow relationships are typically expressed in terms of the number of moves per

hour, the quantity of goods to be moved per shift, the turnover rate for inventory,

the number of documents processed per month, and the monthly expenditures for

labor and materials.

A

flow process may be described in terms of the subject of flow, the resources that bring about the flow, and the communications that

coordinate the resources.

The

subject is the item to be processed. The resources that bring about flow are

the processing and transportation facilities required to accomplish the

required flow. The communications that coordinate the resources include the

procedures that facilitate the management of the flow process.

If

the flow process being considered is the flow of materials into a manufacturing

facility, the flow process is typically referred to as a materials management system. The subjects of material management

systems are the materials, parts, and supplies purchased by a firm and required

for the production of its product. The resources of material management systems

include:

1.

The production control and purchasing functions

2.

The vendors

3.

The transportation and material handling equipment required to move the materials,

parts, and supplies

4.

The receiving, storage, and accounting functions

If

the flow of materials, parts, and supplies within a manufacturing facility is

to be the subject of the flow process, the process is called the material flow system. The type of material flow system is

determined by the makeup of the activities or planning departments among which

materials flow. There are four types of production planning departments (figure

1):

1.

Production line departments

2. Fixed material

location departments

3. Product family

departments

4. Process

departments

The

material flow systems for each department type are shown in fig The subjects of

material flow systems are the materials, parts, and supplies used by a firm in

manufacturing its products. The resources of material flow systems include:

1. The production

control and quality control departments

2.

The manufacturing, assembly, and storage departments

3.

The material handling equipment required to move materials, parts, and supplies.

4.

The warehouse.

If

the flow of products from a manufacturing facility is to be the subject of the

flow, the flow process is referred to as the physical

distribution system. The subject of physical distribution systems

are the finished goods produced by a firm. The resources of physical

distribution systems include:

1. The customer

2. The sales and

accounting departments and warehouses

3. The material

handling and transportation equipment required to move the finished product

4.

The distributors of the finished products.

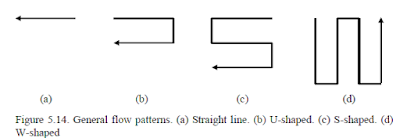

Flow Patterns

Patterns of flow may be viewed from

the perspective of flow within workstations, within departments, and between

departments.

Flow

within Workstations

Motion studies and ergonomics

considerations are important in establishing the flow within workstations. For

example, flow within a workstation should be simultaneous, symmetrical,

natural, rhythmical, and habitual.

Flow

Within Departments

The flow pattern within departments is

dependent on the type of department. In a product and/or product family

department, the flow of work follows the product flow.

End-to-end, back-to-back, and

odd-angle flow patterns are indicative of product departments where one

operator works at each workstation. Front-to-front flow patterns are used when

one operator works on two workstations and circular flow patterns are used when

one operator works on more than two workstations.

In a process department, little flow

should occur between workstations within departments. Flow typically occurs

between workstations and aisles. Flow patterns are dictated by the orientation

of the workstations to the aisles.

Diagonal flow

patterns are typically used in conjunction with one-way aisles. Aisles that

support diagonal flow pattern often require less space than aisles with either parallel

or perpendicular workstation-aisle arrangements. However, one-way aisles also

result in less flexibility. Therefore, diagonal flow patterns are not utilized

often.

Flow between

Departments

An important consideration in

combining the flow patterns shown in figure 5.14 is the location of the

entrance and exit. As a result of the plot plan or building construction, the

location of the entrance (receiving department) and exit (shipping department)

is often fixed at a given location and flow within the facility conform to

these restrictions. A few examples of how flow within a facility may be planned

to conform to entrance and exit restrictions are given in figure.

No comments:

Post a Comment